WhatsApp)

WhatsApp)

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

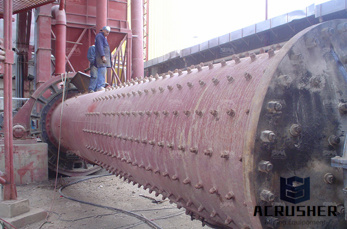

Working. In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30 ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Do you want to be a better CNC''er in 37 Seconds? Get Better Tool Life, Surface Finish, and Material Removal Rates Fast. It''s that easy. You can install and get ...

84 0J HQWHU RI JUDYLW RI WKH FKDUJH G)UDFWLRQ F F Figure Simplified calculation of the torque required to turn a mill. RI FULWLFDO VSHHG 3RZHU

Gulin Machinery is a specialist manufacturer of Coal beneficiation plant. It supplies a variety crusher equipments and also design complete pair of Coal beneficiation ...

Manufactures a range of separation, filtering, drying, grinding, and classification equipment for the processing industries. Product information and offers selection ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

Tailings, also called mine dumps, culm dumps, slimes, tails, refuse, leach residue or slickens, are the materials left over after the process of separating the ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

III11 SAG MILL CIRCUIT OPTIMISATION AT ERNEST HENRY MINING S. Strohmayr 1, W. Valery 2 Jr. 1Ernest Henry – Concentrator Operations Superintendent

contents pt krakatau steel (persero) tbk profile company 4 flat product manufacturing overview 6 steel slab product 7 1. dimension 7 2. tolerance 7

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Four Facet Drill sharpening/grinding jigs for the home shop | drill point splitter

Grinding Media Grinding media are the means used to crush or grind material in a mill. It comes in different forms such as alumina oxide balls, ceramic cylinders, or ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

b) List of Primary Lending Institutions (PLI) (Scheduled Commercial Banks, State Financial Corporation (SFC) the NSIC Ltd, Cooperative Banks, Regional Rural Banks ...

Manufacturer of Wood Chipper MultiUtility Wood Chipper and Shredder, Heavy Duty Wood Chipper RJKHDWC15/20, Heavy Duty Wood Chipper RJKHDWC30 and .

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

Steele manufactures a complete line of crushing grinding equipment for bulk raw material preparation.

Equipment for metallurgy Development and delivery of complex projects for metallurgy on the turnkey basis. For more than ten years, the Department of metallurgy of ...

The common site for tube and pipe industries Tube mills,cutoff, bending, end forming, branching, welding and tube suppliers around the world

Note: Click here to go directly to metallic media specifications or here for nonmetallic media specs. Grinding media, the objects used to refine material and reduce ...

METSIM® The Premier SteadyState Dynamic Process Simulator. HOME FEATURES MODULES APPLICATIONS USERS DOWNLOADS CONTACTS. The basis for analysis of all chemical and ...

WhatsApp)

WhatsApp)