WhatsApp)

WhatsApp)

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

How to Use a Ball Mill Safely and Effectively I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal.

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball mills. ... In a system where makeup balls are added to a mill to compensate for ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Sep 05, 2011· ball mill input up to 10 mm mill for sale. ball mill input up to 10 mm. View/Open University of the Witwatersrand sized product, and mixing does not ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process Control

Tickets for Concerts, Sports, Theatre and More Online at

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Stirred Milling 5 Fewer Moving Parts Ball Mill SMD Vertimill Motor √ √ √ Reducer √ Couplings √ √ √ Hyrostatic Bearing √ Bearing Lube Unit√

The SAG Mill is a machine that grinds items down into other items. ... Input: Where items and ... Optional Grinding Balls can be placed here for increased efficiency;

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its .

2 Light Duty Hydrostatic OIL LEVEL COLD The Eaton Light Duty Hydrostatic Transmission consists of a variable displacement radial ball piston hydraulic pump, a fixed ...

Space saving size and capable of real work: The Tormach PCNC 770 is far more than your typical benchtop CNC mill a real machine tool for the small shop.

Choose Your Weapon 2 Action, Fighting The virus has mutated... good thing Glowmonkey has some new weapons! Eliminate the virus.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

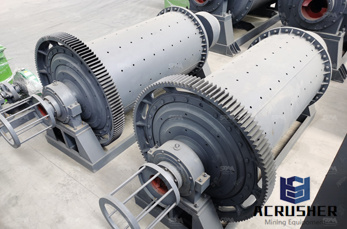

Ball milling machine, ball mill manufacturers. ... CGM ball mills can be divided into two types that are exactly tabular ... Ball Quantity (t) Input Size (mm ...

Have what it takes to be a ball person at a pro tennis tournament? Ye, we thought so, too. When the Open begins at Flushing Meadows on August 28, a whole fleet ...

Ball State is studentcentered, sustainable, and communityengaged. We transform entrepreneurial learners into capable leaders.

Building a Ball Mill By Jeff Thorsgaard, Thorsgaard_foundry Building the Machine. I built a ball mill from looking at a picture of one on the internet.

Learn how to build a ball mill for grinding solids into fine powders. Commercial ball mills can cost more than 100, but with this tutorial you''ll be able to make one ...

Make a Skateboard is a radical activity for gnarly skaters of all ages!

How to Size a Ball Mill Design Calculator Formula. ... Ball milling – a ball mill with a diameter of meters, ... input program: – gr dat; well ...

WhatsApp)

WhatsApp)