WhatsApp)

WhatsApp)

process of clean and dirty air test for coal mills. determination of coal mill fineness. Dirty air test equipment. Chat now>>

COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY . COAL ... Mill Performance Criteria FINENESS, COAL GRINDABILITY ... Mill Fineness ...

1 Coal mill performances optimization through noninvasive online coal fineness monitoring . S. Collura, D. Possanzini Loccioni Group . .

Achieving Optimum Pulverizer Performance Innovative ... utilize a pulverizer or mill to grind coal to a desired fineness and subsequently transport the coal to the ...

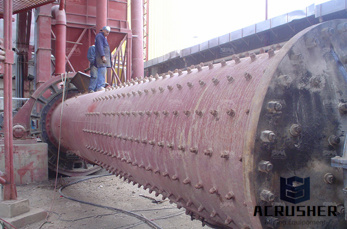

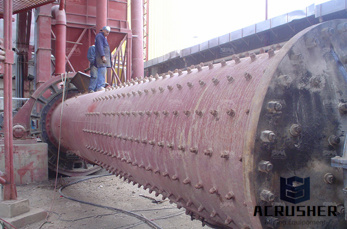

Coal Mill in Power Plantcoal mill in power plant Mill Plant Introduction: The mill plant is widely used in metallurgy, building materials, chemicals, mining minerals ...

Achieving Optimum Pulverizer Performance Innovative . utilize a pulverizer or mill to grind coal to a desired fineness and subsequently transport the coal to the ...

Improved Coal Fineness Improves Performance, Reduces Emissions; Improved Coal Fineness Improves Performance, ... Coal fineness is a .

Efficiency Improvements in Coal Fired Utilities AsiaPacific . Jan 31, 2010 . activities were linked and used to achieve the APP project objective, using the ...

Improved Coal Fineness Improves Performance, Reduces Emissions Improved Coal Fineness Improves Performance, Reduces Emissions. 10/01/2011 Scott A. Vierstra, ...

coal mill fineness in thermal power plant Hot Products. Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in t.

Instead of maximizing coal fineness improvements only, the dynamic classifiers can be used to increase mill capacity while improving the preretrofit fineness level ...

ASME: Performance and operational issues at the Boardman Coal,The results from each test provide coal fineness, coal pipe velocity and coal pipe mass flow Routine ...

ASME Coal Fineness Sampling Test Procedure Innovative ... However, we also realize that most labs trend pulverizer fineness on a weekly or monthly ...

The large scatter of the fineness of pulverized coal,serious boiler slagging phenomenon . of the rotary separator of coal mill is thus reform ...

Coal Pulverizers Primary Air Duct Duct Balloon pulveriser maintenance, leaky damper, coal mill. ... Improve coal fineness to ...

emissions and satisfactory coal burnout. Improving the fineness of coal mill output using a dynamic classifier is the most effective measure to improve coal.

utilize a pulverizer or mill to grind coal to a desired fineness and ... Innovative Combustion Technologies . Coal ... Innovative Combustion Technologies, Inc.

Pulverized Coal Pipe Testing and Balancing; ... The next step in this plant is to upgrade the mill to improve coal fineness to 75% passing a 200mesh sieve.

Pulverizing coal is essential to make a coalfired station work. Magotteaux ... Coal pulverizing in power stations. ... fineness and capacity) based on known coal ...

LoescheMills for solid fuels. Finished product rate[t/h] Fineness fine coarse difficult ... 1 Loesche mill 2 Raw coal feed 3 Filter/Product separation 4 Product silo ...

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates.

determination of coal mill fineness. coal mill fineness sampling probe availability In each case, crushers for coal sampling coal mill fineness sampling probe .

Vertical Coal Mill product fineness of 80μmR 3%, with steady and average product fineness. Application Cement Plant, Vertical Coal Mill, also known as ...

how to improve coal fineness in xrp 763 coal . coal mill xrp operation design parameters how to improve coal fineness in xrp 763 coal mill,Bowl Mills the raw coal ...

WhatsApp)

WhatsApp)